Understanding Spectrometers

A spectrometer is a scientific instrument that separates and measures the spectral components of a phenomenon[1]. In practice, most users mean an optical spectrometer – a device that records the intensity of light as a function of wavelength (or frequency)[2][1]. By using dispersive elements (prisms or diffraction gratings), optical spectrometers demultiplex incoming light into its constituent colors and measure each band, yielding a spectrum[1][3]. The broad use of spectrometers in fields from astronomy to chemistry stems from their ability to reveal chemical composition: “each element leaves its spectral signature in the pattern of lines observed, so a spectral analysis can reveal the composition of the object being analyzed”[4]. In modern form, compact bench and handheld spectrometers use diffraction gratings and array detectors (e.g. CCD/CMOS) to capture high-resolution spectra quickly[3][2]. Optical spectrometers typically operate in the ultraviolet, visible, and infrared ranges of the spectrum[2], enabling applications from UV protein assays to NIR material analysis.

Early spectrometers, from Newton’s prisms to 19th-century lab instruments, were bulky and limited. Over decades, engineers miniaturized optical benches and developed integrated electronics, improving speed and sensitivity. Today’s instruments often use cooled detectors, advanced readout electronics, and fiber-optic inputs. They are used for absorption/reflectance analysis, fluorescence, Raman scattering, and many other modes. Spectrometers measure intensity vs. wavelength, and if calibrated for power they become spectroradiometers[4][3]. They remain indispensable in industrial quality control, environmental monitoring, biomedical diagnostics, and fundamental research.

Current Advances in Spectrometer Technology

Spectrometer technology is rapidly advancing on multiple fronts. Miniaturization and Integration: Researchers are creating ever smaller spectrometers by leveraging nanophotonics and semiconductor fabrication. For example, miniaturized computational spectrometers use on-chip filters or interferometers with computational reconstruction to shrink device size while maintaining performance[5]. Advances in silicon photonics allow dispersers and filters to be fabricated at chip scale, enabling spectrometers small enough to fit on a smartphone[6][7]. Such designs encode spectral information with few detectors and use algorithms to reconstruct the full spectrum. These chip-scale spectrometers can achieve high resolution and signal-to-noise ratios (SNR) within footprints just tens of microns across[5][6].

Enhanced Detectors and Electronics

Modern spectrometers benefit from high-performance detector arrays and electronics. Cooling CCDs or InGaAs arrays reduces thermal noise, boosting sensitivity. Back-thinned CCDs and deep-cooled InGaAs detectors achieve very high quantum efficiency over wide bandwidths. For example, Avantes’ AvaSpec-HERO uses a 1024×58 back-illuminated, TE-cooled CCD and a high-performance ADC to achieve 1,200:1 SNR in a 5 ms scan[8]. Many devices now offer multi-gigabit USB or Ethernet, on-board averaging, and digital I/O for synchronization (e.g. trigger inputs)[9][10]. These improve dynamic range and integration flexibility. Some spectrometers (like Ocean Insight’s QE Pro) provide Stirling- or TE-cooling for MCT detectors in the mid-IR, enabling NIR spectroscopy with very low thermal background.

Speed and Throughput

Frame-transfer CCDs and fast readout electronics allow kilohertz scanning speeds in some spectrometers, useful for high-throughput sensing. “Super-fast” designs such as Ocean FX series target >100 kHz rates (with binning) for laser monitoring[11]. Advanced analog-to-digital converters (ADC) with low noise also boost performance: the AvaSpec-HERO’s AS7010 ADC delivers high speed with excellent noise performance[12]. Novel methods like compressed sensing in computational spectrometers can trade spatial information for faster acquisition times[7].

New Modalities

Beyond traditional Czerny–Turner designs, spectrometers now use holographic gratings, echelle gratings, or Fabry–Pérot etalons for specialized purposes. Some spectrometers integrate multiple channels or multi-order echelle optics to cover UV–NIR in one package. Tunable filter-based designs (e.g. acousto-optic or MEMS Fabry–Pérot) offer compact scanning spectrometers with no moving parts. Also emerging are hyperspectral imagers which capture 2D spatial plus spectral data cubes, leveraging similar technology.

In summary, current spectrometers are smaller, faster, and more sensitive than ever. Research reviews note that “recent advancements in nanophotonics and computational techniques have contributed to new spectrometer designs characterized by miniaturization and enhanced performance”[5]. Engineers combine these innovations for tailored solutions: fiber-coupled modules for OEMs, rugged handheld units, benchtop research instruments, and even chip-scale sensors embedded in consumer devices. This technological progress underlies the rise of modular spectrometers – compact, flexible units designed for easy integration into larger systems.

Emergence of Modular Spectrometers

A modular spectrometer (often called a fiber-optic or miniaturized spectrometer) is a compact instrument whose design emphasizes flexibility and integration. Rather than a fixed bench instrument, these spectrometers are built from modular components: an input (typically via SMA/FC fiber connector), interchangeable slits or filters, a dispersive element (grating or prism), and a detector. Users can customize elements – for example choosing different gratings or detectors – to meet diverse applications[13]. The modular design usually means fiber-optic coupling, so the spectrometer can be placed conveniently (e.g. in an instrument housing or at-line analyzer) while sampling via remote fiber probes. This concept suits OEM integrators and field applications, where the spectrometer needs to link to other hardware or fit tight spaces.

The modern modular spectrometer traces its roots to the early 1990s. Ocean Optics (now Ocean Insight) pioneered miniaturized fiber spectrometers. Their first product, the S1000, introduced a “modular, compact” fiber-optic spectrometer concept in 1992[14]. The later Flame series exemplified this: with dozens of optional gratings, filters, slits and accessories, it offered thousands of build-to-order configurations[14]. As one reseller notes: “Ocean Optics’ Flame Spectrometer employs a classic model of modular design and build-to-order options… the legacy of this approach goes back to the original S1000 spectrometer invented in 1992. With the options now available, the number of primary model variations is 4,680… we set out to build Flame spectrometers that could meet ANY need”[14]. This modular philosophy – interchangeable optical benches and sampling accessories – became standard in the fiber spectrometer market.

Over time, more companies embraced modular spectrometers. New entrants (such as StellarNet, Andor, B&W Tek, Horiba/Jobin Yvon, etc.) released fiber-coupled OEM spectrometers with compact footprints. Many integrate their spectrometer engine into larger instruments (spectrophotometers, gas analyzers, process probes). In parallel, academic and hobbyist projects have even built 3D-printed modular spectrometers with plug-in modules for teaching and research[6]. The core idea remains: separate the optical dispersion/detection part from the sample interface, so that users can configure each part for the application.

Today’s modular spectrometers typically feature:

– Fiber-optic input: SMA905 or FC connectors are standard, allowing easy connection to fibers, probes, or collimators. A fiber port means the spectrometer can be optically bench-mounted or hidden, while the fiber brings light from the sample.

– Interchangeable Slits and Gratings: Users can select slit widths and gratings for desired resolution and wavelength range. Some designs allow field-replaceable slits (e.g. Avantes slit kits[15]).

– Compact, Rigid Housing: The optical bench is miniaturized (often 25–100 mm focal length). Ocean Insight’s “SR” series or Avantes’ HSC benches are examples[16][17].

– Flexible Electronics: Many modular spectrometers expose external boards or connectors for I/O (USB, TTL triggers, analog outputs). The Riki series, for instance, “features an external circuit board… optimized for seamless instrument integration”[18].

These advances were driven by market demand. Industrial and OEM users need to embed spectrometers in machinery or networks. Academic researchers require adaptable setups. The modular design allows the same spectrometer to serve in lab, production line, or handheld tester roles. As Lontenoe explains: “Modular spectrometers are compact, customizable instruments… Their modular design allows users to tailor components – such as detectors, light sources, and sampling accessories – to specific applications[13].” This flexibility makes them ideal for industries from pharmaceuticals to environmental monitoring to material analysis.

Applications of Modular Spectrometers

Modular (fiber-optic) spectrometers are used across a remarkably wide range of fields. Their combination of compactness, sensitivity, and flexibility suits many scenarios. Key application areas include:

- Material Science and Chemical Analysis:In laboratories and factories, spectrometers analyze solids, liquids, and gases to determine composition. Fiber-coupled spectrometers measure absorption or transmission spectra of chemicals, enabling material identification and quality control. They can be used in UV-vis chemical assays or NIR polymer classification. For example, a fiber-optic transmission system was used to measure filter transmittance and gelatin samples, demonstrating reliable spectral characterization[19]. In chemical labs, modular spectrometers serve as the detector in flow cells or cuvette holders for quantitative analysis.

- Biomedical Diagnostics:Spectrometers analyze biological samples (blood, tissues, DNA) for medical diagnostics. Modular spectrometers are used in point-of-care devices (e.g. glucose monitoring via optical absorption), or in immunoassays (absorbance/fluorescence). Fluorescence spectrometers using fiber probes help detect biomarkers. The same fiber probe technology allows invasive or non-invasive measurements (e.g. in endoscopic probes).

- Environmental Monitoring:Rapid detection of pollutants in air and water is a major application. Fiber-optic UV-vis spectrometers monitor water quality (e.g. turbidity, nitrate levels) on-site. In atmospheric sensing, spectrometers detect gases by their absorption lines (for example, using special gas cells with optical fibers). A review notes that fiber-optic spectrometers are “widely applied” to environmental monitoring (water/air quality)[20]. Compact spectrometers are used on drones or buoys for remote sensing of environmental parameters.

- Food and Agriculture:Many food-quality measures rely on spectroscopy. NIR fiber spectrometers assess sugar content, moisture, or adulterants in products. They can detect illegal additives or toxins in food by their spectral signatures[20]. The speed and portability of modular units make them suitable for field inspections of crops and goods.

- Optical Component Testing:Manufacturers of lenses, filters, LEDs, and photonic devices use spectrometers to characterize components. A modular spectrometer can measure the transmission spectrum of an optical filter or the emission spectrum of an LED, providing passband edges or color coordinates. A fiber-coupled integrating sphere accessory plus spectrometer yields uniform light measurement for photometry or material testing.

- Industrial Process Control:In-process monitoring often uses spectrometers: for example, monitoring the concentration of a solute in a flowing stream (e.g. paper bleaching by measuring optical density), or measuring fabric dyes in textile production. Fiber spectrometers with robust housings can withstand factory environments. They feed data to PLCs or PCs via USB/Ethernet.

- Research and Education:In academic labs and teaching labs, fiber-optic spectrometers are indispensable tools. They are used in chemistry and physics labs to demonstrate spectroscopy. Students can perform absorption or fluorescence experiments using simple fiber probes, learning principles of spectroscopy. Because they can be attached to microscope objectives, modular spectrometers also enable optical spectroscopy at the microscopic scale (fiber-coupled Raman microscopes, for example). As one educational application note puts it, such systems “help students understand the basic principles and methods of spectroscopic analysis”[21].

In short, modular spectrometers serve material analysis, chemical and biomedical testing, environmental and food safety monitoring, optical component characterization, industrial process control, and education[19][22]. Their high precision, wide wavelength coverage, and fast response (combined with fiber coupling) make them extremely versatile[23][19]. The list of applications continues to grow as industries adopt fiber-optic sensing (for example, optical coherence tomography uses specialized spectrometers for imaging).

Riki High-Sensitivity Modular Spectrometer vs. Mainstream Products

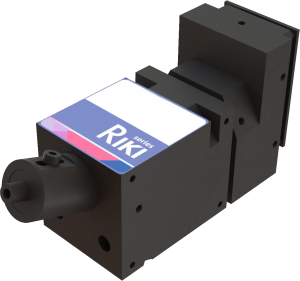

The Riki High-Sensitivity Modular Spectrometer (by LONTENOE) is designed for rapid industrial detection and OEM integration. Its key specifications are (see Table below): it covers 400–800 nm with ~3–4 nm optical resolution (50 μm slit), achieves ~300:1 SNR (at full signal), and has a very compact footprint (128×60×41 mm)[24][25]. It provides SMA-905 fiber input and USB 2.0 output on an exposed circuit board, emphasizing ease of integration[18][26]. We compare Riki to comparable mainstream modular spectrometers from Avantes and Ocean Insight:

Parameter | Riki (Lontenoe) | Avantes AvaSpec-HERO | Ocean Insight QE Pro |

Wavelength Range | 400–800 nm[27] | 200–1,160 nm[8] | 190–1,100 nm[28] |

Optical Resolution | ~3–4 nm (with 50 μm slit)[27] | 0.2–7 nm (configurable)[8] | 1.2–6.87 nm[28] |

Signal-to-Noise | 300:1 (single scan)[29] | 1,200:1 (10 ms, cooled CCD)[30] | 1,000:1 (10 ms)[28] |

Fiber Interface | SMA-905 (preinstalled)[18] | SMA via replaceable slit[31] | SMA-905[32] |

Communications | USB 2.0 (I/O port)[26] | USB 3.0 & Gigabit Ethernet[33] | USB Type-C (USB 2.0 speeds)[32] |

Dimensions (mm) | 128×60×41[25] | 185×161×185[34] | 182×110×47[16] |

Weight | 430 g[25] | 3,500 g[35] | 1.15 kg[16] |

Sources: Riki data from LONTENOE Riki product sheet[24][25]. Avantes and Ocean Insight data from published specifications[8][28].

In this comparison, Riki’s strengths are its compact size and modular integration. It is substantially smaller and lighter than the Avantes HERO or Ocean QE Pro (by an order of magnitude in volume), making it easier to embed in space-constrained instruments. The Riki’s external circuit board exposes its interfaces for OEM use, whereas many bench spectrometers encapsulate all optics and electronics in one heavy enclosure. Riki’s SMA fiber input and USB port support straightforward “plug-and-play” connections[18], similar to mainstream devices but in a smaller package. LONTENOE also notes Riki’s customizability: users can swap gratings or slits to meet specific requirements[36].

On performance, Avantes and Ocean models offer higher resolution and sensitivity. The AvaSpec-HERO, with its cooled CCD, achieves 1,200:1 SNR and sub-nm resolution[30], far exceeding Riki’s 300:1. Similarly, the QE Pro attains 1,000:1 SNR[28]. However, such performance comes with larger size and higher cost. Riki is optimized for “rapid industrial detection” where volume production integration and cost-efficiency may be more important than ultra-high sensitivity. It still delivers respectable performance (up to 10 kHz scan rate, dynamic range ~2×10^8)[37] suitable for many process monitoring tasks.

In summary, mainstream spectrometers like Avantes AvaSpec and Ocean Insight QE Pro emphasize maximal sensitivity and resolution (often using cooled detectors and larger benches)[30][28]. Riki, by contrast, targets OEM-friendly flexibility: a bare-board design with modest volume size and sufficient performance for rapid detection. Its advantages include small form factor (suitable for portable or embedded use), plug-and-play interfacing, and cost-effectiveness. For example, Riki’s 128×60×41 mm package can fit into handheld devices or robotic fixtures, whereas competitors’ bench spectrometers occupy several liters. LONTENOE’s focus on industrial users is reflected in Riki’s features: the product description highlights “an external circuit board optimized for seamless instrument integration”[18], illustrating how it caters to OEM integrators.

LONTENOE: Innovative Modular Spectrometer Solutions

LONTENOE is an optoelectronics company that “blends innovation with precision to deliver advanced optoelectronic solutions”[38]. As a high-tech enterprise (with roots in university research), LONTENOE offers a comprehensive portfolio of spectrometers across UV, visible, and NIR. Besides Riki, its modular spectrometer lineup includes the LUNA series (miniature bench spectrometers), FURI (high-performance spectrometers with cooling options), LINA (NIR-focused spectrometers), and NAGA (ultra-compact spectrometers for handheld use)[39]. Each series targets different needs: routine lab analysis, high-end research, industrial monitoring, or field measurements[40][41]. This modular approach – offering multiple form factors and wavelength ranges – reflects LONTENOE’s goal of meeting diverse customer applications.

LONTENOE emphasizes customer-centric customization. Indeed, the Riki’s feature list stresses custom design and user-specific configurability[44]. This aligns with LONTENOE’s stated values of innovation and collaboration. For example, in the Riki spec sheet, LONTENOE highlights that Riki is “customizable to meet specific user requirements”[45]. In practical terms, LONTENOE supports OEM integrators by offering modules (like Riki) that can be built into new instruments, or complete spectrometer assemblies with tailored slit/grating choices.

Industries can benefit from LONTENOE’s range. For instance, fiber-coupled spectrometers from LONTENOE are used in agricultural product testing, solar wafer inspection, manufacturing QC, life sciences, and semiconductors, as indicated by examples on their site[46]. The company also provides accessories (like fiber probes and light sources) and complete systems (Raman analyzers, gas sensors) that integrate with their spectrometers. Overall, LONTENOE positions itself as a one-stop provider for spectral instrumentation, empowering research and industry alike[38].

In conclusion, the evolution of spectrometers toward modular designs has opened new capabilities in sensing and analysis. Modular spectrometers like LONTENOE’s Riki combine compactness with configurability, making them ideal for modern industrial and OEM applications.

References.

[1] [4] Spectrometer – Wikipedia

[2] [3] What is a Spectrometer? – Edinburgh Instruments

[5] [6] [7] Review of Miniaturized Computational Spectrometers

[8] [9] [12] [15] [17] [30] [31] [33] [34] [35] AvaSpec-HERO – Avantes | Your Partner In Spectroscopy

[10] [16] [28] [32] High Sensitivity Spectrometers | Ocean Optics

[11] [14] General Purpose & OEM Archives – Spectrecology

[13] [39] [40] Modular Spectrometer – Lontenoe

[18] [24] [25] [26] [27] [29] [36] [37] [41] [44] [45] Riki High-Sensitivity Modular Spectrometer – lontenoe

[19] [20] [21] [22] [23] News – Applications of the Fiber Optic Spectrometer Transmission System